|

COPPER GUTTER REPAIR |

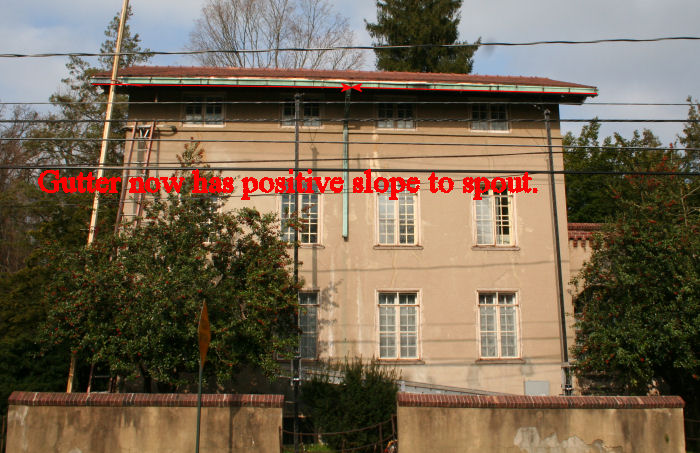

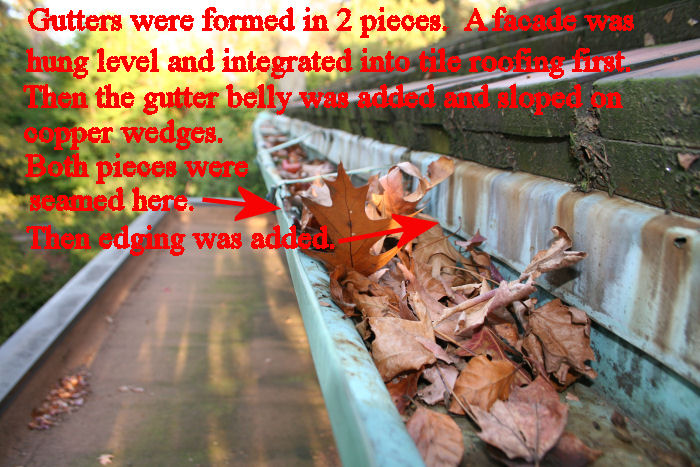

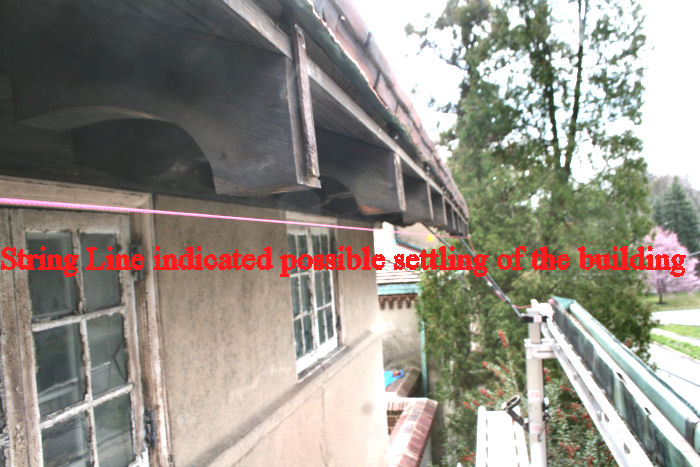

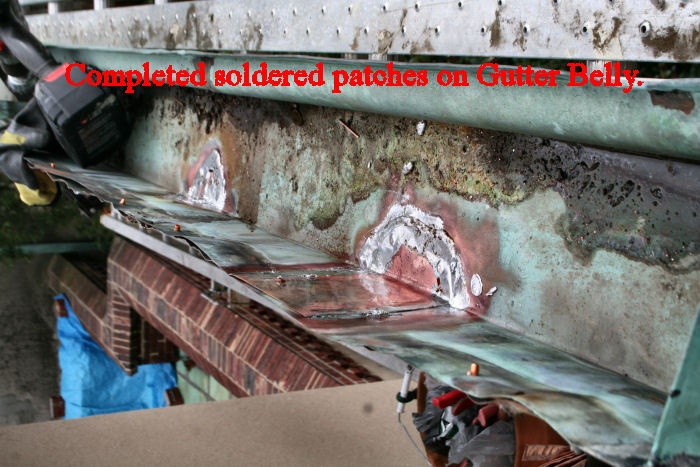

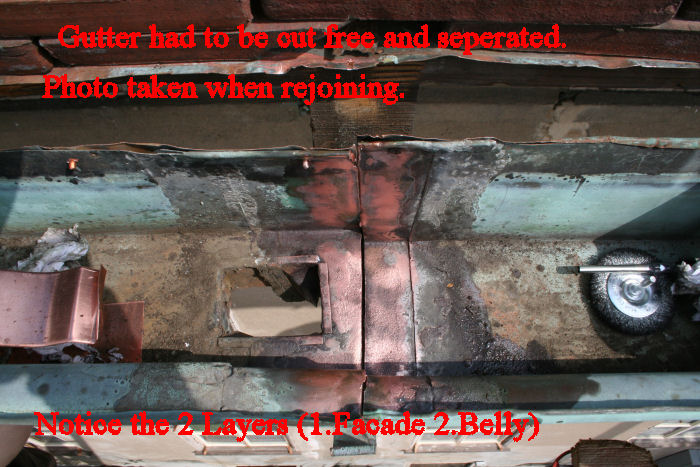

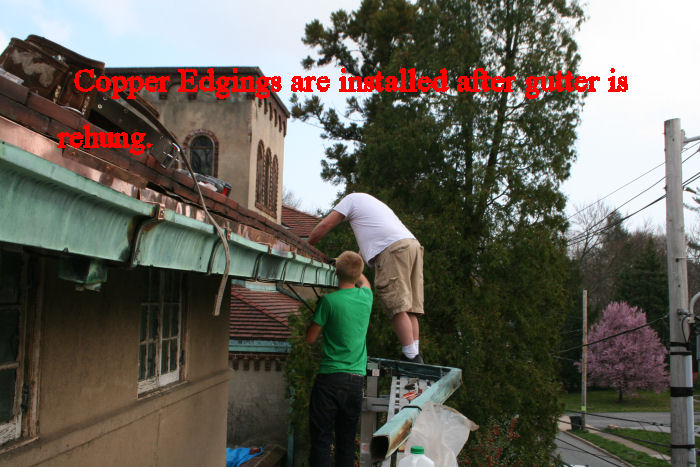

Contact Us today for a no-hassle Gutter Estimate As you can see in the photograph above, the existing copper gutter on this home in Ardmore, Pa. was sagging on the ends and holding water on the ends. This gutter was one of the first of its kind of a custom Ogee design with a double layer of soft copper. Soft copper has proven to hold up well during thermal movement without cracking the seams. The outside layer was a facade to give the appearance of level cornice. The gutter belly resided inside the facade and was originally sloped with progressive copper wedges. Still the gutter was failing and something had to be done to restore this copper gutter or it would be lost. The following is a portion of a response from our client in a letter of reference regarding this job and other work on the same site: "I have had FSI complete several repairs to my home that were challenging,requiring a level of skill and creative thought that most roofing companies would not be able to undertake. ?Bob and his workers have impressed me on each round of repairs with their thorough ?grasp of the project and masterful completion of the work. ?In each instance, FSI has exceeded my expectations with fine work, reasonable pricing, ?a great work crew, and a timely completion of the job."

We lowered the center of the old gutter approximately 2 inches. The line level indicated we had positive slope to the center. The large level placed in the gutter belly indicated definate positive slope, with the added original gutter belly pitch in the original design. The old brass hangers had to be modified because we progressively lowered the center.

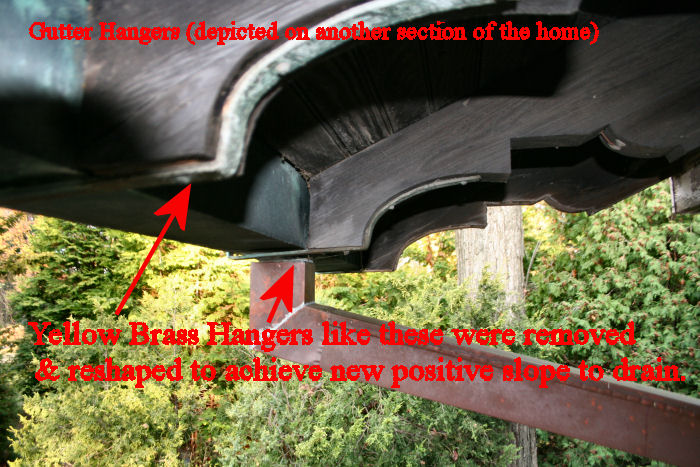

Heavy Brass Wrap-Around hangers were used to hold this gutter in place. These Yellow Brass Hangers had to be removed and hammered and reshaped to accommodate our new slope.

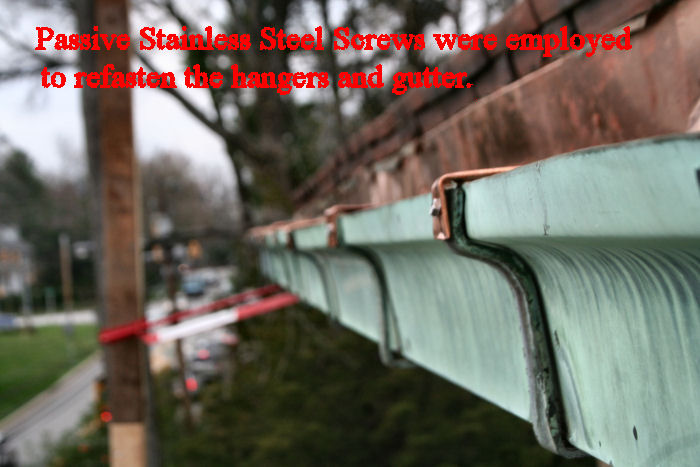

As stated the gutter was of double thickness. The first layer provided a level facade and the belly was sloped much in the way we slope an integral box gutter. Somewhere over the years, possibly from settling, some of these gutters sagged and were not working properly.

It is important to use the proper fasteners when installing any metal in the field. This job required very strong metal fasteners that would not react metallurgically with the copper (electrolysis). Passive stainless fasteners were used for the gutter fastening.

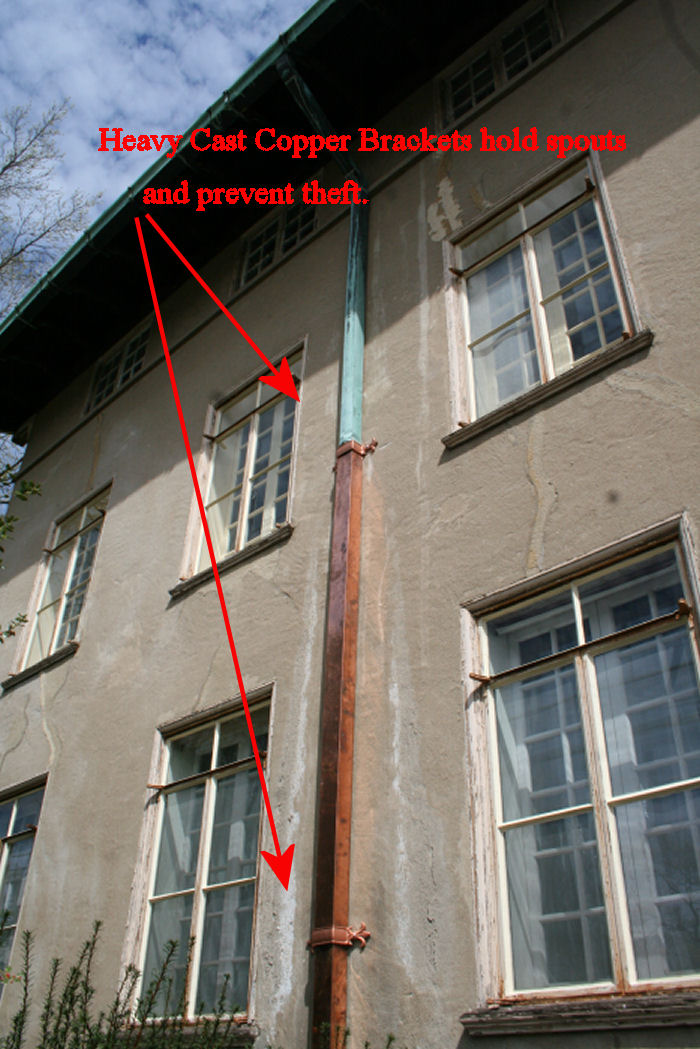

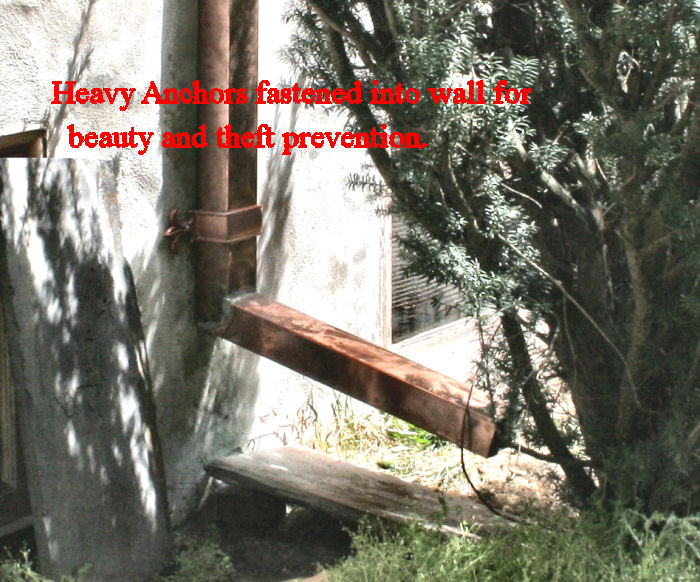

Original Copper Downspouts had fallen victim to thieves.

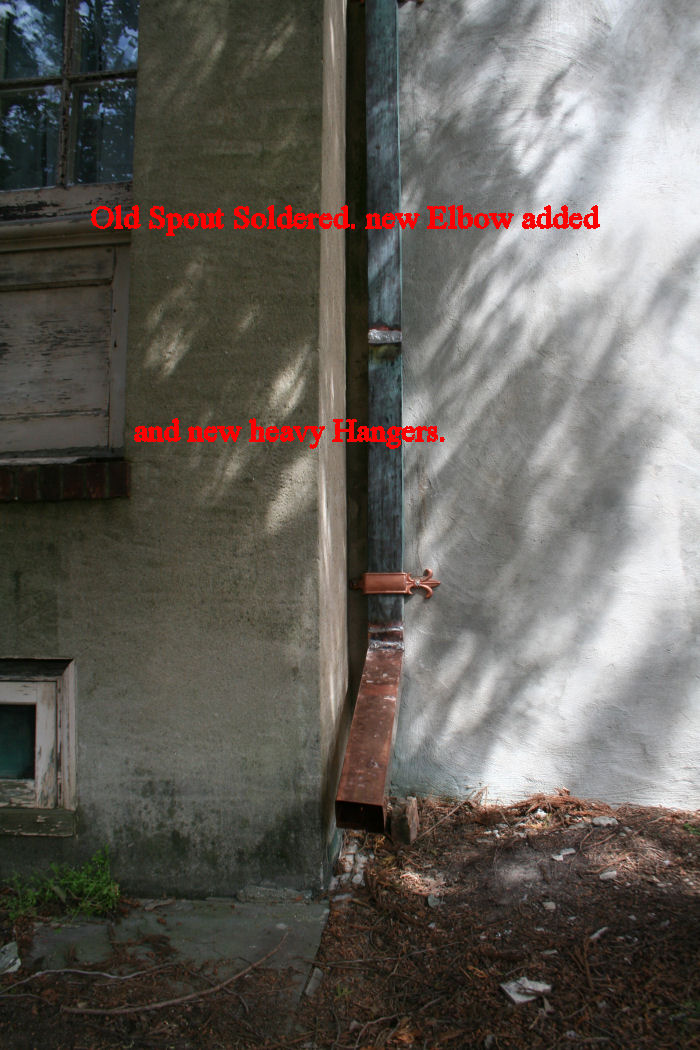

Custom copper downspout transition (above).

Heavy Cast Copper Brackets were anchored into walls to secure custom copper downspouts.

|

|||||||||||||||||||||||