|

|

Mold and Rot Hidden Inside Walls

|

"We have received calls from architects and engineers that differ with us on key points listed on this website. This page should serve for increased discussion on the topic of vapor barriers or retarders and their proper placement within the building envelope."

"When called on a siding estimate, suggesting to a potential client that moisture vapor is traveling through their walls and then condensing on the outside, under the paint seems like the most ridiculous thing they have ever heard."

Since building codes, self-serving manufacturer recommendations and "expert" opinions seem to lead to many problems as evidenced in the field, we are pragmatic in our approach to solving these issues that present themselves as we perform our services. We have learned from real world experiences. LOOK AT WHAT DOING THE JOB WITH DISREGARD TO PROVEN METHODS CAN CAUSE: MOLD IN THE WALLS, FLOORS AND ROT AND MAJOR DAMAGE FROM ROOF AND SIDING LEAKS!

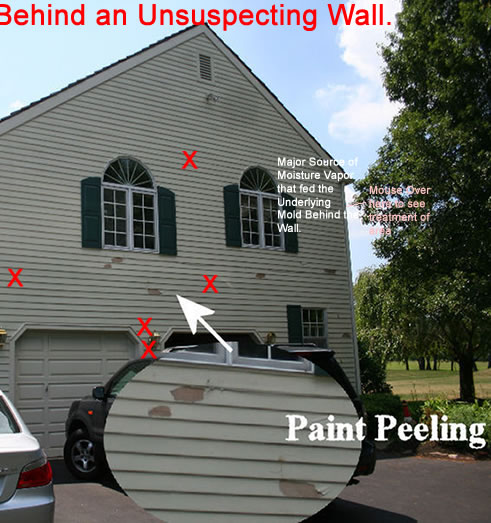

We have received calls from architects and engineers that differ with us on key points listed on this website. This page should serve for increased discussion on the topic of vapor barriers or retarders and their proper placement within the building envelope. The highlighted job on this page originally resulted from a call about chipping paint on the outside of a wood sided home. The cost of repainting and the failures of prior painting efforts caused for the consideration of the replacement of the wood siding with Fiber Cement siding. This type of problem is common and often seen as merely a paint issue. Expert painters gave their opinions on this situation. The consensus from the painters was that the original wood was not primed on the backside. This is a reason often given by paint experts regarding chipping paint. Our estimator knew better. Just a quick look in the back yard told him that the house was built on a high water table. There stood a raised "sand mound" or "Wisconsin mound" for the septic system. He knew that when a building site fails a PERC test, it is indicative of a high water table and the raised mound is then required. The high water table is indicative of several potential problems with a home built in such an area. The water bags on the outside of the home were not even realized by the homeowners. They only knew the paint was peeling, after the water bags in the paint broke. Many homes in the area have similar problems with paint peeling. The homes in the area that used a semi-transparent stain did not have the water bags and peeling issues. Clearly moisture was coming from within the wall and being trapped by the new-age paint that formed a latex envelope over the walls. Moisture vapor was pushed through the walls in the winter and condensing on the cold external wrapping of latex paint, forming water bags that stretch the paint at the bevel laps, undoing its adhesion from the substrate. The "paint blisters" or "water bags" that form then break away from the weight of the water, usually freezing on the wall. The missing paint is what is left.

As shown in the interactive image, serious mold and rot usually accompany the moisture issues. Hidden inside the walls of the subject home were entire colonies of different fungi that were threatening not only the structure of the home but the health of the occupants. As shown, in areas of direct leakage was a semi-aggressive white rot that had established itself in the several strongholds located in direct proximity to and under actual external water leaking areas. The mold however, had proliferated because of high interior relative humidity and this combined with the sporadically concentrated humid areas like that of bathrooms, etc., created the perfect storm behind the walls. The lack of exhaust fans in the bathrooms also contributed to these issues.

Since this home was built in 1986, it falls on the "cusp" of the onset of the new growth era in the building marketplace. Aspenite on the walls was very vulnerable to mold proliferation. The framing seemed semi-resilient to the white rot and appeared to be old growth wood. Customer was advised as to moisture problems and to use an indoor hygrometer and dehumidifier and to check on the basement floor and walls. The high water table is the most probable source of the obvious winter-time high indoor relative humidity. A "doormat" test for the presence of a vapor barrier under the basement slab (not to be confused with, the often problematic, vertical vapor barriers installed on basement walls) is always a good place to start. |

||||||||||||||||||||||||||||

Mold remediation Philadelphia Main Line areaMold inside walls |

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

For years we have sounded the alarms regarding construction practices that cause major problems that can prove to be unhealthy to homeowners and their families. Any contributing factor that would encourage the growth of black mold within the walls of a home should be investigated. Black mold is dangerous and the health affects are just now being discovered.

For years we have sounded the alarms regarding construction practices that cause major problems that can prove to be unhealthy to homeowners and their families. Any contributing factor that would encourage the growth of black mold within the walls of a home should be investigated. Black mold is dangerous and the health affects are just now being discovered.