|

"Most of our work comes from fixing bad jobs..."

If you are in the market for a new roof, you probably just want to get on with it, right? Have you heard too many sales pitches and want the truth? Most of our work comes from fixing bad jobs from companies that had promised the world to their clients. |

"...roof repairs and replacements to mold remediation and interior damage.."

This includes everything from roof repairs and replacements to mold remediation and interior damage resulting from poor installation. Did you know that the interior damage is not usually covered in the big factory warranties? To get a manufacturer to pay for these kinds of repairs you would have to raise tort and liability issues that have nothing to do with warranties...more on that later... The industry is such that the percentage of premature failure of asphalt shingle roofing is very high. It is not always the fault of the roofer or the manufacturer.

"We just ask that you not be sucked in..."

In these cases, the homeowner ends up holding the bag. Many times it takes more than a "one trade" company to look over your entire situation to make a wise and educated recommendation. We try to convey all of the information you will need to make an informed decision on what you need and only what you need. If you don't need a roof, we won't try to sell you one.

We provide ventilation charts with the government recommendations for your home so that you won't get stuck in a warranty dispute with a shingle failure due to improper ventilation. This is more common than you think. We just ask that you not be sucked in by the packaged sales endeavors that attempt to cover the obvious unacceptable failure rate in the industry. The cover is being made by "factory" or "manufacturer" certifications, extended warranties, fear tactics and the like.

"The truth is that manufacturer warranties are based on volume.."

The truth is that manufacturer warranties are based on volume and that most roofers don't stay in business long enough to know how to install a roof properly. Manufacturers are not educating roofers because the hired representatives of the large companies know very little about roofing themselves. Volume is the drive behind the industry. We reject this approach because we know very well, the fruit of this kind of endeavor.

"Let's not get confused by sales pitches."

We often get to do the clean-up. Please read through our website and then give us a call. We will reveal things you won't hear anywhere else. If you choose to do business with us, you will be happy that you did. Our roofs last and if there is a material problem down the line, a warranty or an extended warranty will do little for you in getting your job rectified.

"The company that installed your roof must stand behind the work..."

The company that installed your roof must stand behind the work and the product installed, in becoming an advocate for you if you expect to get anywhere with a material manufacturer. Manufacturers will replace bad product and pay for replacement labor if there is a problem with the materials. They don't want the tort and liability exposure, nor do they want the bad name in the marketplace. A "limited" warranty is just a big list of limitations, so why would you pay for this? . Let's not get confused by sales pitches. Please read more about warranties below. |

Do not be fooled by "LIFETIME WARRANTIES"

Why is ventilation so important?

Did you know that all major roofing shingle warranties have stipulations regarding ventilation, but fail to describe, in unambiguous terms, what ventilation is required? Ventilation is very important but contrary to popular opinion, it will not cure some moisture issues in the attic. Moisture feeds microbes that eat the decking from within! Try getting your roofing warranty to cover that kind of damage and you will be out of luck.

Fiberglass

Based Shingled Roofing Must Be Ventilated Properly

The fiberglass base shingles of today are especially susceptible

to heat degradation. Most Roofers do offer a Ridge Vent on every

steep sloped roof, regardless of the existing situation. This is done to address a serious concern, but the measures that are being

employed everyday usually produce an imbalance in ventilation. Nothing could be more ridiculous and potentially harmful than this approach.

The thinking is that hot air rises and it will eventually leave the attic when the roof heats up enough to facilitate the relief

of this heat pressure. This is known as thermal buoyancy. The roofers

of old used this narrow approach and it used to be adequate several decades ago. Today the mere reliance on thermal buoyancy is no longer

adequate and manufacturer warranties are commonly voided because of lack of proper ventilation. Homes have changed and are now tighter than they have ever been. The roofing shingles of today are made

up of only one type of asphalt adhered to a stronger, yet more brittle reinforcement.

Please

ask your field estimator about shingle failures and voided warranties.

No matter how strong the warranty seems, there are caveats for inadequate ventilation. What

is adequate ventilation? Start to answer this by reading the fine

print in the warranty.

More important of a ventilation concern, is the control of disease causing attic mold. Attic mold remediation is just part of the solution to attic mold problems. Moisture control involves ventilation but only after examination by an expert in interior moisture and mold growth. Air Sealing is the most overlooked aspect of attic mold and it is something we routinely facilitate.

Below is a little history of the Asphalt Shingle Industry:

|

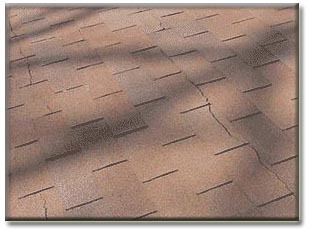

To

the left is a photograph of a roof that when taken,

was only seven years old. The three tab shingle

was rated and warranted for twenty five years. Lateral

cracking was caused by thermal shock from super

heating of the roof deck. The attic was improperly ventilated.

The

warranty coverage was voided because of poor ventilation. |

|

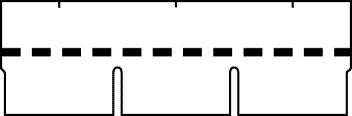

To

the left is a depiction of the basic 3 tab Asphalt

Roofing Shingle. |

Fiberglass

Based Shingles History

In the late 1970’s while the country was transfixed

on the long waiting lines for gasoline, and the

impending threat of being rationed petroleum, the

asphalt roofing shingle industry was in the midst

of radical change. Over the time period of about

five years, the northeast roofing shingle marketplace was dominated by the fiberglass roofing shingle.

This new breed of shingle was a much lighter and

seemingly a more uniform product. The major manufacturers

had made the big switch, it seemed overnight on

their basic three tab roofing shingle.

The

fiberglass base of the shingle was not organic,

would not rot, and did not have to be saturated

with a saturant asphalt, as did the old organic

paper mat base products. The production plants only

needed to apply an adherent asphalt to the mat and attach the granular surfacing and release material

and the lighter and purportedly better products

were ready for packaging. There was a savings on

the amount of asphalt used in manufacture, hence

it seemed even a patriotic effort, given the petrochemical and economic climate of the time.

Shortly

after the onset of these products, some of the downside

of the original design started to show itself in

the field. It was a decade of major improvement

that followed, compensating and improving in that

original product design. Some of the manufacturers touted better seal strips than had ever been seen

in the industry. Some of the manufacturers, like

Johns Manville, produced such a uniform product

that installers were thrilled at the increased ease

of production.

Back to Top

Overlays

with Fiberglass Shingles

Over

the top installations were affected drastically

as installers had to improperly nail (or “nail

high”) the product in order to recover roofs

without the old roof courses showing (or “telegraphing”)

through for a lumpy roof. “High nailing”

commonly caused blow-offs on over-the-top installations.

The increased heat retention of the overlays gave

the fiberglass based products their true field tests.

High heat seemed to degrade the fiberglass shingles

much faster than their organic, heavier, two step asphalt predecessors. The reasons were two fold.

The mat was more brittle and it was common to see

roofs crack laterally, as never seen before. The

adherent – only, more brittle, thinner shingle

was not as malleable, and therefore more susceptible

to thermal shock. The process of reformulating the

products continued. The asphalt mixes were improved

and stricter quality control standards were put

into place.

We

do not advocate reroof overlays - They do not last

- Flashings are ignored - They leak - Please ask

your estimator about this.

Laminated

Shingles

Laminated

Shingles like the GAF Timberline, Certainteed Landmark,

and others are a fantastic value. Improvements on

these products are ongoing, and they are better

now, in several ways, than they have ever been.

In some ways, however, we have lost quality. The original ship-lap design provided a product that

was very uniform and when a roof was properly installed,

the completed roof looked uniform and the butt joints

were virtually invisible. A design was present that

provided a double layer over the nails and the shingles had to be installed in a set stagger system.

Again,

product “improvements” were made to

the original design. The fiberglass mat, asphalt,

and seal downs were upgraded. A company named ELK

started to produce a much more inexpensive laminated

roofing shingle that moved marginally through the

northeast market, and seemingly, at the time in the early 1980’s, made no real significant

impact on the industry. The manufacturing process

used by ELK was several times faster than the major

manufacturers' original hand-laminated offerings.

The price for the ELK products was significantly

less than that of the major manufacturers' products that included the shiplap and double coverage design

over critical areas. The big manufacturers, within

a decade, had changed over to a similar “In

Line Laminate Process,” similar to that originally

used by ELK. This process replaced the original

hand laminate process and the original ship-lap

laminated shingle design disappeared from the roofing

marketplace. With it, the uniform look of the laminated

roof also was lost. The impact on the laminated roof shingle design is that the butt joints are

random and steeper roofs will show the butt joints.

This concern leads some people away from the laminated

shingles on some jobs. The up side is that the improvements

have afforded the manufacturers the ability to rate the warranted life expectancy to double that of

the original products on the higher end laminates.

These products have become a real value in the asphalt

shingle industry. We do caution their use on some

high profile and steep roofs, however.

|

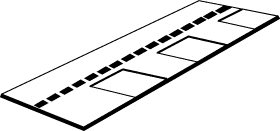

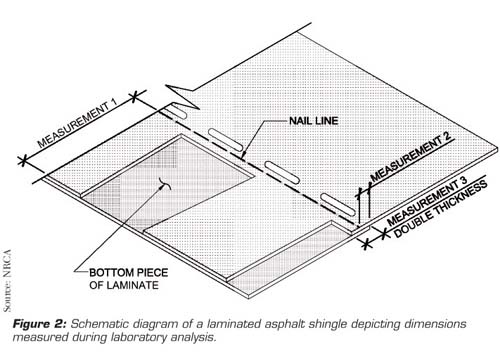

| To the right

is a laminated two piece roofing shingle (GAF Timberline).

Below is the same shingle depicted at a different

angle. |

|

|

| Above is a depiction of a two-piece laminate roofing

shingle. The black dashes represent the seal downs.

The lap of the two layers is a 5/8" area that

extends up from the exposure line (just below the

black stripes) to the bottom of the black dashes.

The nails must be placed on a line that runs right

in the middle of the two. |

Laminated

Shingles on Steep Slopes

The two-piece

laminated shingles must be mechanically fastened

through the lap of both layers on steep sloped

applications. These shingles should also be double

nailed on steep slopes. The lap that must be penetrated

for proper mechanical fastening is only 5/8”

in width. This lap area in the design does not

give an adequate holding strength on many steep

sloped roofs. Steep roof applications should be

scrutinized before consideration of this type

of shingle. |

|

Steep

slopes are no place for architectural laminate shingles.

As you can see in the photographs, delaminating

can occur when the full weight of the lower laminated

double layer is suspended on the mechanical fasteners.

Mansards and steep sloped roofs should always be storm nailed (double nailed).

The argument

has been made for installer error in these situations,

but in defense of many installers, this shingle

design affords only a 5/8” overlap through

which a roofing nail is to be fastened. The laminate

bond alone will not hold the two piece shingle

together. Even double nailing is often not enough

to hold these shingles on steep slopes. The bottom

line……..Don’t use architectural

laminates on steep slopes.

Don't

just take our word - Read

the article in Pro Roofing Mag - written with kindly "Kid's

Gloves," but still very informing. NAIL PLACEMENT ON LAMINATE SHINGLES

From

the above cited article: "For example,

NRCA has received a significant number of reports

about the bottommost pieces of some laminated asphalt

shingles loosening, becoming detached and falling

from roofs."

Designer

Shingles

There are designer products that are the best asphalt

shingles money can buy. These products are dual-laminated

and tri-laminated products. They are higher in price

than the laminated shingles, but they are uniform

and they have no two part base shingle design issues to consider in the fastening of the shingles. The

color patterns of the application of the granular

surfacing materials are computer enhanced to give

dramatic affects on several of the higher end products.

The shadow lines are engineered to complement the added bulk of the shingles. These products are usually

lifetime roofs and they are super-heavyweight products.

|

|