2018 - CELLEBRATING 40 YEARS!

JAMES HARDIE

NICHIHA

FIBER CEMENT SIDING

When your Stucco is failing, consider Fiber Cement Siding!

When replacing your stucco, go with a viable, fire resitant, solid cement based product - That doesn't leak!

PHILADELPHIA STUCCO REMEDIATION - REPLACEMENT

If you have a roof deck with Stucco above, get the same company to rectify both problems.

"The difference between an applicator and a tradesman is in the details."

NATIONAL AWARD WINNER FOR INNOVATIVE USE OF FIBERCEMENT

FIBERCEMENT SIDING IS YOUR ANSWER

Recent article from: http://www.askthebuilder.com/ "Cement siding is a most interesting product. It has been around for over 100 years, very much like cork flooring. It gained widespread acceptance as many row houses used it to resist "frost, fire & ants." Those claims are so true! I know of 15 houses within three miles that have it on the sides and roofs of the houses. What is mind-boggling is that the material has been in place since 1910 or so! The houses that have it as siding show no signs of blistering or peeling. If this isn't a reason for you to check out all the manufacturers listed below, then I don't know what is!

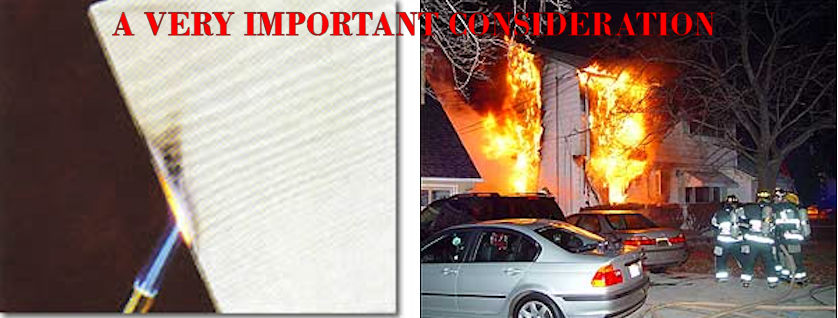

3 STORY LIMIT IMPOSED - NOT BECAUSE OF THE LEAKS BUT BECAUSE OF THE FIRE HAZARD:

LIMITATIONS• In general, the use of vinyl siding is allowed in Type V and V-B construction and other types of construction when certain test results are demonstrated according to IBC 1406.• Vinyl siding is allowed on buildings where the ultimate wind speed does not exceed 100 mph and the building height is 40 feet or less. Note: If the building exceeds these conditions then documentation may be provided to show necessary adequate performance.• Polypropylene siding has the same limitations as vinyl siding, except it is only allowed on Type V-B construction.• Insulated vinyl siding limitations will be listed in the code compliance report.• IBC Table 602 and IBC 705.5 place certain fire resistive ratings on walls depending on the occupancy, type and size of building based on ASTM E119 tests.• Vinyl siding is a part of many UL rated E119 assemblies. In addition vinyl siding is allowed to be part of IBC 722’s calculated fire resistive approach.• IBC 1406 allows the use of vinyl siding (and other combustible cladding) with Types I, II, III, IV under certain conditions as long as its application is 40 feet or less height above plane. • If combustible vinyl siding is used with Types I, II, III, IV construction, it must be tested in accordance with NFPA 268 (IBC 1406.2.1.1) and perform to certain levels depending on the fire separation distance (density) of the building.

Unlike Vinyl, Fiber Cement is Solid

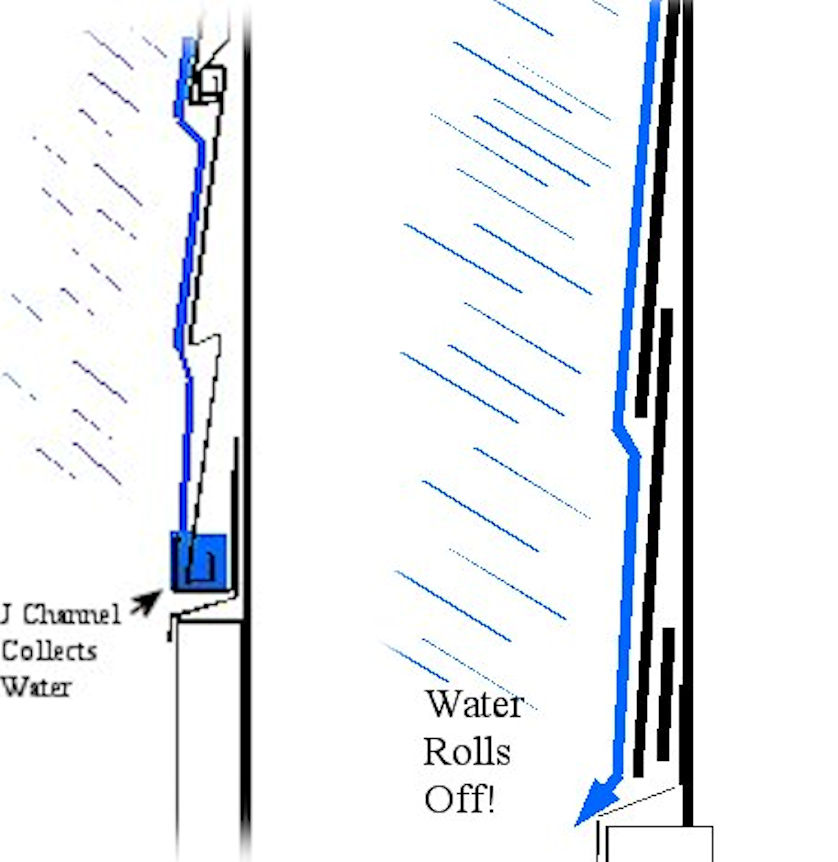

Unlike Vinyl, Fiber Cement doesn't leak!

Unlike Vinyl, Fiber Cement is Fire Resistant!

Fiber Cement can be installed over 3 Stories Legally!

MAJOR CONCERN: NEW SIDING SHOULD NOT LEAK!

READ: THE WEATHER BARRIER STATEMENT

DANGER - BEWARE OF THE "HOUSEWRAP MENTALITY"

Wrapping Up a House may cause Mold! Either by Paint or by Underlayment, Mold is fed by condensing moisture behind the wall.Underlayment Craze has left many problems.

|

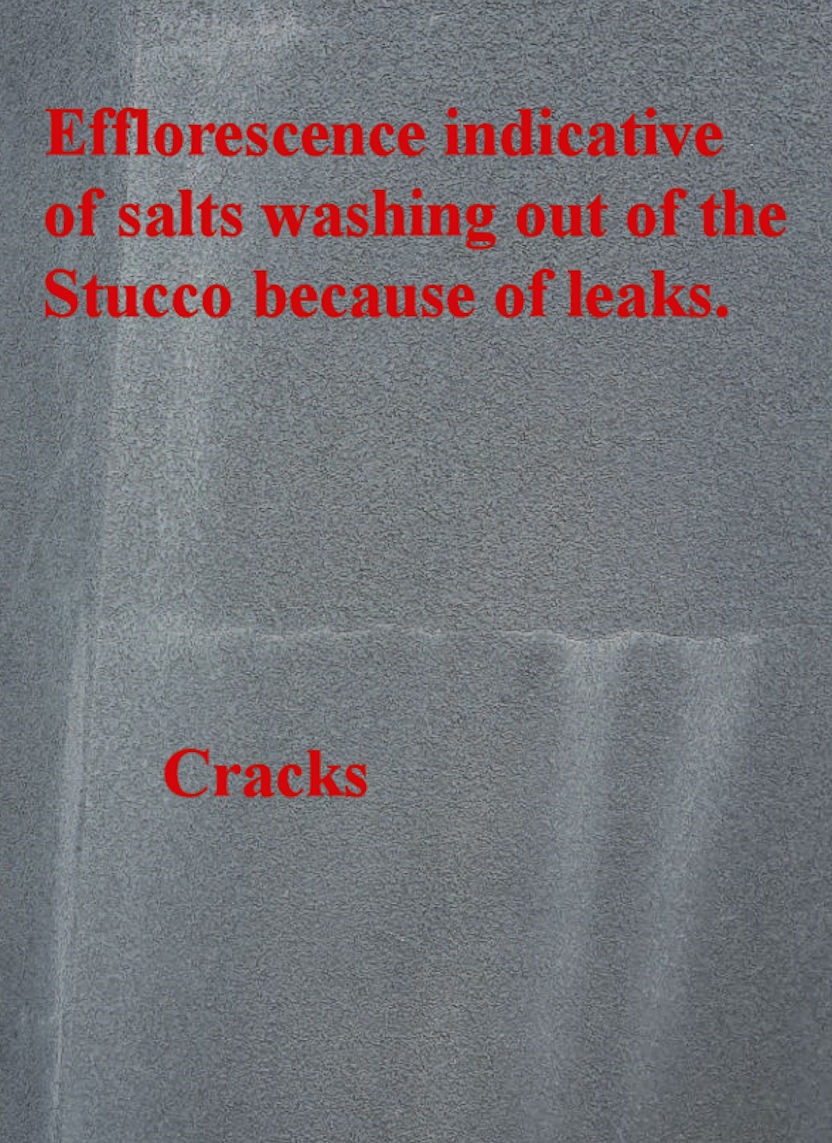

IF YOU HAVE FAILING STUCCO, IT IS IMPORTANT THAT YOU UNDERSTAND WHY IT IS FAILING:

We have a lot to offer: OVER 40 YEARS OF EXPERIENCE, INFORMATION, ADVICE, OPTIONS. We do not follow the whims of a flawed industry. "Olde World Craftsmen Meeting the Challenges of today!

The Subcontractors that create these problems are actually now in the business of fixing their own problems at your expense! DO NOT REPEAT THE CYCLE! The builders use these cheap subcontractors in the creation of the problems and now they want you to pay them again. You need an experienced company that stands behind their work. 10 Year Warranty on repairs.

■Over 40 Years Experience!

Free Estimate link is below (in green).

Call an expert with many years of experience and get the straight story - the truth!