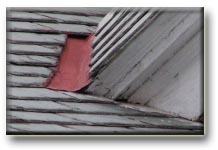

| There are several methods of Valley methods including: Weaved Valley, Closed Valley, Step Flashed Valley,Tucked and Cut Valley. For discussion we are highlighting the Open Metal Valley: |

|

|

|

| It is never advisable to apply Asphalt Roof Cement, or any other sealant to the Metal Valleys and Flashings of any roof! READ WHY |

|

|

For instance,

Terne Coated Tin, or Steel (of the last century and a half) was

often employed as valley linings and flashings in areas where

anthracite coal usage was the main energy source of heating. The

soot, heavily laden with sulfur from the chimneys, would degrade

the copper roof flashings rather rapidly in urban areas. |

| Whether it

is the replacement of old Terne Flashings on an old, yet viable

Slate Roof (Such as Vermont Slate, or even a viable Pa. Black

Slate, etc.) or the installation of a new Roofing System, Copper

Open Valleys offer a lifetime of protection, while affording an

accompaniment level of enhancement to the rooftop. |

|

|

|

|

Many of the

new super heavyweight asphalt roofing shingles must be installed

with open valleys. The metal of choice is almost always copper

at the 16 oz. per sq. ft. grade. Occasionally, a property owner

would opt for lead coated copper (now not available because of environmental concerns), which has a sacrificial layer

of lead that will extend the life of the metal in the face of

a potential damaging element in the environment. Sometimes, the

irregularities of copper patinas are not to the liking of the

client, and the lead coated copper offers a silver color and more

uniform appearance. Zinc is the now available as a sacrificial coat for copper. Also, the new Terne II by Follansbee (Zinc

coated Steel) is showing promise as a favorite. TCSII is a Terne coated stainless steel base by Follansbee. |

Caution on

the following:

Never use copper on Cedar Shake & Shingle Roofs

Never use Aluminum as a Valley Lining

Always use Slip Sheet

Never Fasten Metal with direct fastening (Use Cleats)

Below are photos of Open Copper Valleys and Blind Fastened Ridge Roll. |

|

|

|

| Back to Top |

|

Environmental

Elements that affect Copper |

|

| |

|

|

|

|