A slate roof that is not only beautiful, but it comes with a story. See more about it by clicking on the red tab.

Job Story Page

These roof tiles last a long time, a really long time: They can be removed and reinstalled for another lifetime of service when the nails are no onger holding them.

Job Story Page

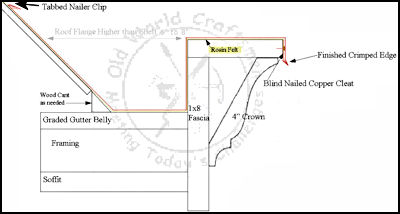

Custom Copper Integral Guttering takes not only skill but planning. There is a whole more to it than just fabrication and installation. Continue to read about how it is done so it will last without seam failure, etc.

Link to Related Topics

We were the first to call it out... Once a viable option for a long lasting roof cladding, the industry is finally agreeing with us that New Growth Cedar is not what it used to be.

Commentary

Flashings are the most neglected areas because they take the most time. Most Roofers are for the most part just single-trade applicators looking to do as little as is possible and sealants and tar just will not do the job!

Job Page

We are old-school as you will see. New Age metal will make the roof on your home look like it belongs on a shopping center.

Job Page

Low Sloped Roofing done in Flat Lock Seamed Copper and Soldered with an Iron dates back the founding of this country. This is similar to Flat Lock Seamed TinPlate Roofing.

Job Pics

Metal Roofing was once an art. Today's offerings are prefabricated than ever relying on rubber seals that wear out - What is the sense? Faux Standing Seam Roofing is not really Old World Craftsmanship

Commentary

We have the knowledge. We have the experience. No other company comes close to our level of expertise. Since 1978 we have serviced the exterior needs of clients throughout the Delaware Valley. Many have entered the trades since that time and many have gone. We remain devoted to the methods that work and shun new-age nonsense. Much of the manufacturer driven products are flawed primarily because the imperative for maximizing profit has been put before the ideals of solid specifications. The industry is always in flux and building codes cannot keep up the pace. “Refer to the manufacturer specifications” is the common thread in any area where codes are not up to date and the testing ground has become the very field where there should be assurance of proper methods, not the guesswork of new-age offerings.

Our techs have knowledge of all facets of your rooftop that can affect the success of the installation.

They are trained and overseen by seasoned life-long trade professionals.

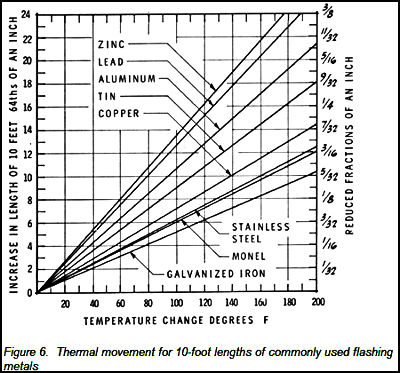

Read about Open Valleys on Slate and Natural Roofs and why the type of metal chosen is so important

Commentary

Pipe penetrations have been around since modern indoor plumbing was implemented. They need permanent Pipe Jacks. Neoprene Boots do not last. Get an authentic Pipe Jack that will last as long as your roof.

YouTube Video

Shocking it is to find that big name roofers are actually mixing metals on their flashing details. You don’t have to be a scientist – just don’t mix metals.

Link to Related Topics

When you see shiny copper, you know that it is being eaten by acid. Ever since Follansbee discontinued Terne Coated Steel, misguided industry specifiers and installers thought it was a good idea to use copper instead. This is a big mistake and you will see it a lot if you look for it.

Commentary

It takes a lot more than the equipment and knowledge of fabricating metal to successfully install one of these integral gutters. Failure looms when novices attempt this work.

Expert Commentary

Our competitors will direct fasten metal. They screw it down and caulk it and cause kinking and blow-offs and failure. You have to allow for thermal movement.

Expert Commentary

Proper Flashings are often skipped in favor of a sealant, etc. There is no substitute for proper metal work. An artisan will do the job right. A hack will try to get away with not doing these very important elements.

Custom Flashings

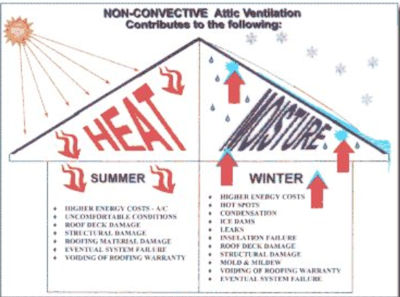

Devastating ice dams are caused by heat. Slate roofs seem to have some immunity because of less hotspots - but not always.

Expert Commentary

Mold in the attic is a mystery to some people and contractors alike. Many say that ventilation is the answer. It is not. Get the facts. Gain understanding. Click below.

Valuable Information

Natural Roofs always were immune to the many problems that we find are common today but with modern energy conserving homes that are tighter, additional measures are required to prevent the attic problems of mold, mildew, etc.

Commentary

Never Vinyl Siding! It leaks! FiberCement Siding is one of the best sidewall claddings.

GalleryThere are and always have been novices. "Roofers" are not necessarily 'Slaters' and in most cases they are not. The slate & copper arena should be left to the professionals because rooftops are ruined evey day by those who know little about natural rooftops.

Every year a new company, or two will pop up to take the place of the ones that folded last year. It is sad but true. Stay with us and we will stay with you with the best warranty coverage in the business.

You have our word that our main focus is doing right by you. We will inspect your roof and accompaniments free of charge and you will receive a true report as to the condition with options that fit your needs. We will not lie to you to make a buck. We will not withhold information in order to present a proposal knowing that you will be hit with additional charges later. Contractors do this and it is wrong. We only offer what will work because we will be here tomorrow to service our work.

We are family run and we care. We care about getting the details right first. Profit is a reward and it comes after the job is done right. Every member of our team will value your home as if it were their own. We are clean, respectful, honorable and we do the right thing every day. That is why we have become the company trusted by so many homeowners in the Delaware Valley.

We stand behind our work for 10 years. We will show up to service our workmanship free of charge in response to your request. We put it in writing on day one when you receive your estimate.